The Best Guide To Roar Solutions

The Best Guide To Roar Solutions

Blog Article

Excitement About Roar Solutions

Table of ContentsHow Roar Solutions can Save You Time, Stress, and Money.See This Report about Roar SolutionsThe Ultimate Guide To Roar SolutionsHow Roar Solutions can Save You Time, Stress, and Money.

The equipment register is a detailed data source of devices documents that consists of a minimum set of areas to recognize each item's location, technological parameters, Ex-spouse classification, age, and environmental information. This information is vital for tracking and managing the devices properly within unsafe areas. In comparison, for periodic or RBI tasting assessments, the grade will be a mix of In-depth and Close assessments. The proportion of Comprehensive to Shut examinations will be determined by the Tools Threat, which is examined based on ignition danger (the probability of a resource of ignition versus the possibility of a combustible atmosphere )and the unsafe area category( Zone 0, 1, or 2). This variant will likewise affect the resourcing needs for job prep work. As soon as Whole lots are specified, you can develop tasting plans based on the sample dimension of each Whole lot, which describes the variety of random tools things to be inspected. To figure out the needed example size, two elements require to be assessed: the dimension of the Lot and the classification of examination, which shows the degree of initiative that must be used( decreased, typical, or enhanced )to the evaluation of the Whole lot. By incorporating the group of examination with the Whole lot dimension, you can after that establish the appropriate denial standards for an example, indicating the allowed variety of malfunctioning products found within that sample. For even more details on this process, please refer to the Power Institute Guidelines. The IEC 60079 basic suggests that the maximum period between examinations need to not surpass three years. EEHA inspections will certainly likewise be conducted outside of RBI projects as component of scheduled upkeep and tools overhauls or repair services. These assessments can be credited towards the RBI sample dimensions within the affected Lots. EEHA examinations are carried out to identify mistakes in electrical tools. A weighted racking up system is vital, as a solitary tool might have multiple mistakes, each with varying degrees of ignition risk. If the consolidated rating of both examinations is less than two times the mistake rating, the Great deal is regarded acceptable. If the Great deal is still considered unacceptable, it needs to go through a complete examination or justification, which may trigger more stringent inspection procedures. Accepted Whole lot: The root causes of any kind of mistakes are determined. If an usual failure mode is discovered, added devices may call for evaluation and fixing. Mistakes are classified by extent( Safety, Integrity, House cleaning ), guaranteeing that urgent issues are evaluated and attended to without delay to minimize any influence on security or procedures. The EEHA data source should track and tape the lifecycle of faults together with the restorative activities taken. Implementing a robust Risk-Based Evaluation( RBI )method is crucial for making sure conformity and safety and security in taking care of Electric Equipment in Hazardous Areas( EEHA). Automated Mistake Rating and Lifecycle Management: Effortlessly handle mistakes and track their lifecycle to enhance inspection accuracy. The intro of this support for risk-based evaluation even more reinforces Inspectivity's position as a best-in-class solution for governing conformity, as well as for any asset-centric inspection use case. If you are interested in finding out more, we invite you to request a demonstration and uncover just how our service can transform your EEHA management procedures.

With over one decade of consolidated Ex experience (IECEx/ATEX, EEHA), Saipex began to promote the value of competence of all employees entailed in the Hazardous Area field in 2019. In 2021, our collaboration with IndEx and Tech Ability International (TSI) marked a landmark in the Saipex road to proceed Ex-spouse improvement.

Rumored Buzz on Roar Solutions

In regards to eruptive threat, a dangerous area is a setting in which an eruptive environment exists (or may be expected to be existing) in quantities that need unique safety measures for the building and construction, installment and use of tools. In this write-up we explore the challenges faced in the workplace, the threat control procedures, and the called for proficiencies to work securely.

(https://www.metooo.io/u/roarsolutions)

These materials can, in certain conditions, develop explosive environments and these can have significant and heartbreaking consequences. Most of us are acquainted with the fire triangular get rid of any kind of one of the 3 elements and the fire can not happen, yet what does this mean in the context of hazardous areas?

This is then validated through examination and testing and is maintained throughout the life of the installation by employing the proper maintenance strategies, supplemented by regular assessment. When all these steps are taken, they must additionally be documented. The verification file consists of information such as the dangerous location category drawing, suppliers' documents, equipment qualification, layout drawings and computations, examination records, and records of a person's proficiency and proceeding specialist growth (CPD), such as using ECA's eCOMS software application.

7 Simple Techniques For Roar Solutions

It is critical that trainees comprehend and have a comprehensive understanding regarding what specifically makes up an unsafe location. The pupil ought to additionally know why training is very important before trying to take on job or defining equipment into an unsafe location. These locations are additionally recognized as classified locations and are defined as locations which have a high chance of a surge due to the possible presence of flammable gases, vapors, dusts and so on.

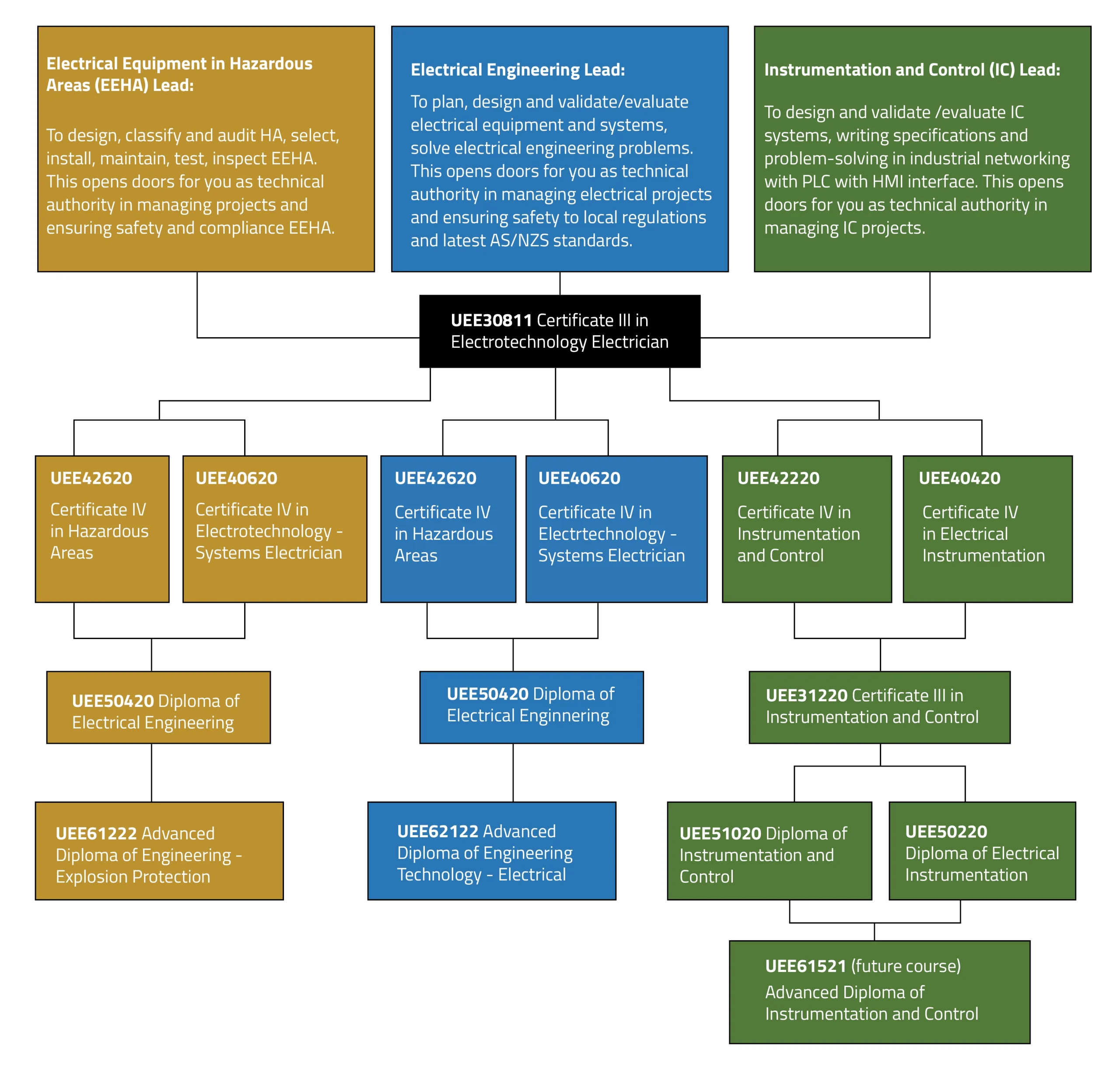

Industries which contain dangerous areas are now demanding that electric employees that are defining or functioning in these locations need to have a hazardous area certification that considers them qualified. Jobs in these industries are extremely satisfying so you need to be prepared. To satisfy this need for the industry, across the country acknowledged training in Certification IV in Dangerous area Electrical and EEHA training on the growth of skilled specialists.

The Best Strategy To Use For Roar Solutions

Tech Abilities Australia is a Registered Training Company providing you with the most cost effective and quickest means in acquiring your credentials - hazardous area course. Our teachers are sector certified and have a number of years of process experience. Our training courses have aided thousands of individuals from business supervisors to day-to-day staff members in getting a solid hang on this not so complicated yet high threat training

The training likewise includes identifying the dangerous areas, resources of surge and the properties of hazardous products together with the obligations and functions of all events, policies, systems, standards and technique codes attached to unsafe areas. We provide instrumentation and unsafe location services that are in conformity to most recent AS/NZS and worldwide market standards.

Report this page